ALI Drives Sustainable Value Creation via the Circular Economy

Ayala Land, Inc (ALI) is closing the loop on the next frontier in resource conservation and sustainability: a circular approach to materials like steel, cement, solid waste and water.

Leading real estate and property developer Ayala Land Inc. is taking its commitment to sustainability a step further by putting into practice a circular approach to waste management and resource efficiency for its developments and operating properties.

As early as 2017, Ayala Land committed to carbon neutrality to control the emissions of its commercial properties. Five years later in 2022, it set a target of net zero emissions by 2050, further solidifying its corporate thrust for climate action, one tangible and quantifiable step at a time.

Now, the real estate firm is making strides towards resource efficiency as part of its four sustainability focus areas towards providing value to business, environment, and society.

Under its resource efficiency pledge, Ayala Land acknowledges its use of a sizeable amount of resources in property and commercial development. In 2023 alone, the company used 201K tons of cement, 62K tons of steel, and generated 39K (39M kg) tons of waste from its operating properties. To ensure it does not contribute to the continuing loss of the country’s natural resources by relying on virgin materials, Ayala Land is adopting a circular economy approach to its usage of steel and cement, among others.

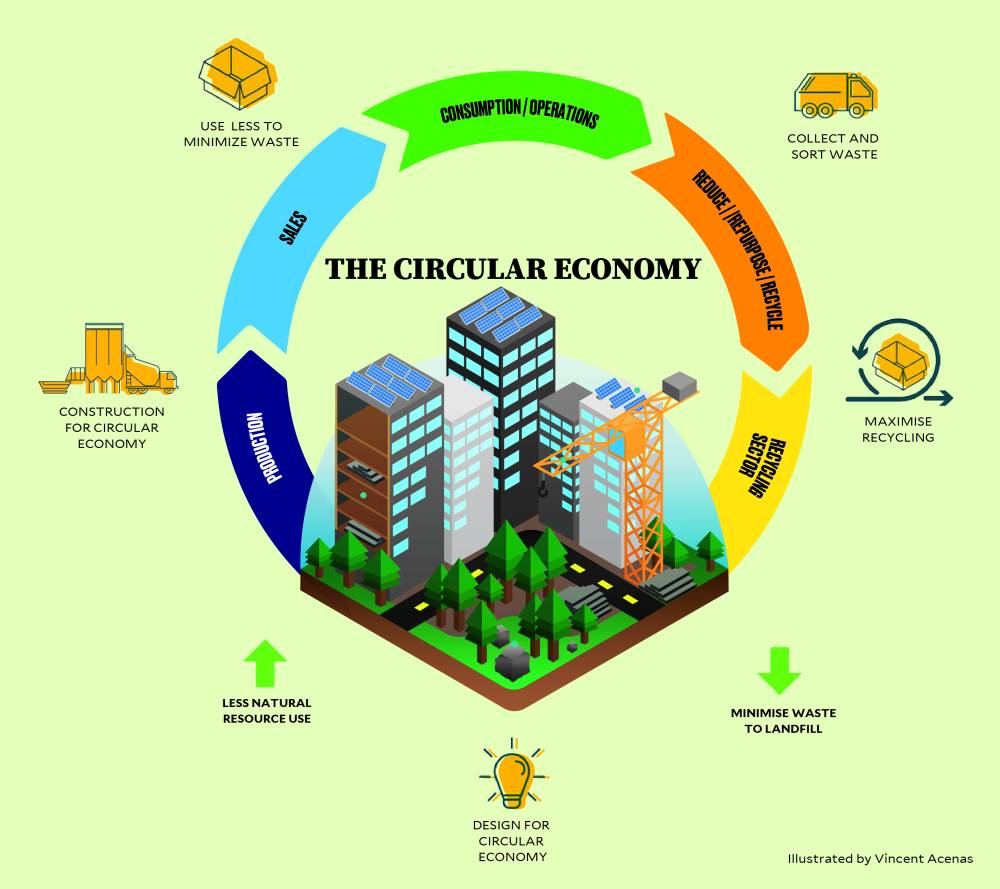

This move is aligned with and supportive of the Sustainable Development Goals (SDG) of the United Nations Development Programme, which defines circular economy as a conscious act of “minimizing waste and promoting sustainable use of natural resources, through smarter product design, longer use, recycling and more, as well as regenerate nature.”

Curbing linear economy models

The status quo for the consumption of energy, water, and materials like steel and cement has always been to take, make, then waste. It’s nowhere near the ideal circular approach that ensures that materials and products are kept in circulation for as long as possible.

The production of construction materials like steel and cement is considered one of the significant sources of carbon emission at every stage, from extraction to utilization. The amount of cement used globally every year is about 14 billion cubic meters. That’s enough to pave the whole state of New York with a ten centimetres-thick slab, and our country twice over.

Iron and steel, on the other hand, is the largest coal consumer and the most greenhouse gas-intensive industry, consuming about seven percent of the global energy supply, and is thought to be responsible for seven to nine percent of global greenhouse gas emissions.

To curb this consumption pattern and its reliance on virgin materials, Ayala Land signed a memorandum of understanding with its construction arm, Makati Development Corporation, and Steel Asia Manufacturing.

Under the agreement, Steel Asia, the country’s largest steel company, will supply MDC with rebars made from recycled content sourced from scrap steel generated by Ayala Land projects, advancing circular economy and decarbonization methods in the construction industry.

Ayala Land is also currently working with a cement company to recycle debris from demolitions so that it can be used as aggregates or concrete inputs in lieu of virgin cement from quarrying. The developer, its partner cement company, and MDC are likewise looking at other applications of debris without compromising building integrity.

Closing the loops

Ayala Land’s foray into circular economy began in earnest in 2019 with a plastic plastic waste collection and processing facility developed with Green Antz, which converts plastic waste into eco-building materials. This earned the real estate firm a gold award at the premier business award program Annual International Business Awards in 2021.

Its pledge to close the loop doesn’t begin with plastics and end with steel and cement either. Water efficiency management has long been observed in its properties via the use of low-flow fixtures and other water conservation best practices. Ayala Land also aims to further decrease potable water use through alternative sources such as recycled water or rainwater harvesting for grounds keeping and landscaping uses, currently being practiced in some estates.

Ayala Land is diverting landscaping and food waste from landfills, too. Last year, it converted 216 tons of yard waste like pruned twigs, branches, and fallen leaves from its commercial and residential locations in Nuvali and Makati to energy via Integrated Waste management, Inc. The resulting energy was used to power a laundry facility in Cavite that services Seda Nuvali and other hotels in its immediate area.

Demonstrating commitment to addressing waste on all fronts, Ayala Land is also looking into rolling out waste diversion programs for different waste profiles across its properties. This will include food waste, whose diversion from dumpsites and landfills should be a top priority as it produces potent methane, a greenhouse gas even more potent than carbon dioxide, as it rots. On-site or off-site processing either through natural or machine-aided methodologies can be effective in addressing this, according to the real estate developer.

Circular economy not only ensures that minimal waste is generated in the afterlife of materials, but it is also a way to honor resources–something we can learn from nature and its way of life. For Ayala Land, this is the most sensible way to go forward in minimizing its impacts to the environment.