Recycling, dismantling as ways to reduce emissions

Reduce. Reuse. Recycle. These three “Rs” have been hammered upon us no end by environment advocates and concerned government agencies. While this primarily addresses the need to conserve precious finite resources and reduce unnecessary wastage, in this era when the repercussions of climate change are being felt worldwide, these “Rs” add another layer of relevance.

Did you know that the practice of recycling between the years 2020 and 2050 is projected to reduce emissions by 5.5 to 6.02 gigatons of carbon dioxide, equivalent to removing over 1 billion cars from the streets for one year?

Making new products from recovered materials requires fewer raw resources and less energy. That’s according to the experts over at Project Drawdown, which categorizes recycling into household, commercial, and industrial materials. These recyclable materials include metals, plastics, glass, rubber, textiles and e-waste.

Recycling helps combat the climate crisis by limiting the use of raw materials and reducing waste going into landfills. According to University of Colorado Boulder, the less energy used to produce an item, the fewer greenhouse gases are emitted in the process. This benefits climate change, as greenhouse gas emissions drive the current climate crisis.

It is important to note that unless done correctly, recycling can emit more greenhouse gases into the atmosphere.

Why should recycling concern every single individual? What if I just throw away one metal canister or a small plastic water bottle? Surely that won’t matter? Well, think again.

According to the book “Breaking Boundaries: The Science of Our Planet, ” every person on earth consumes an average of 14 tons of “stuff” every year. “From minerals to fossil fuels, from crops to trees, the world eats through a staggering 110 billion tons of materials.”

The book is quick to add that most of this consumption is happening in rich or developed nations. “Most of the materials produced are for housing, factories, roads, and other buildings. But transport, food waste, and consumer goods are big ticket items, too. About a third of all these materials are dumped. Economically, this is a phenomenal waste of money. The good news is that close to 10 percent of the global economy is now circular. The potential is vast. In Europe, a more circular economy could cut emissions from heavy industry by 56 percent by 2050,” the book projects.

That’s for the individual consumer. So, what about the big companies that produce consumer goods in overwhelming volumes?

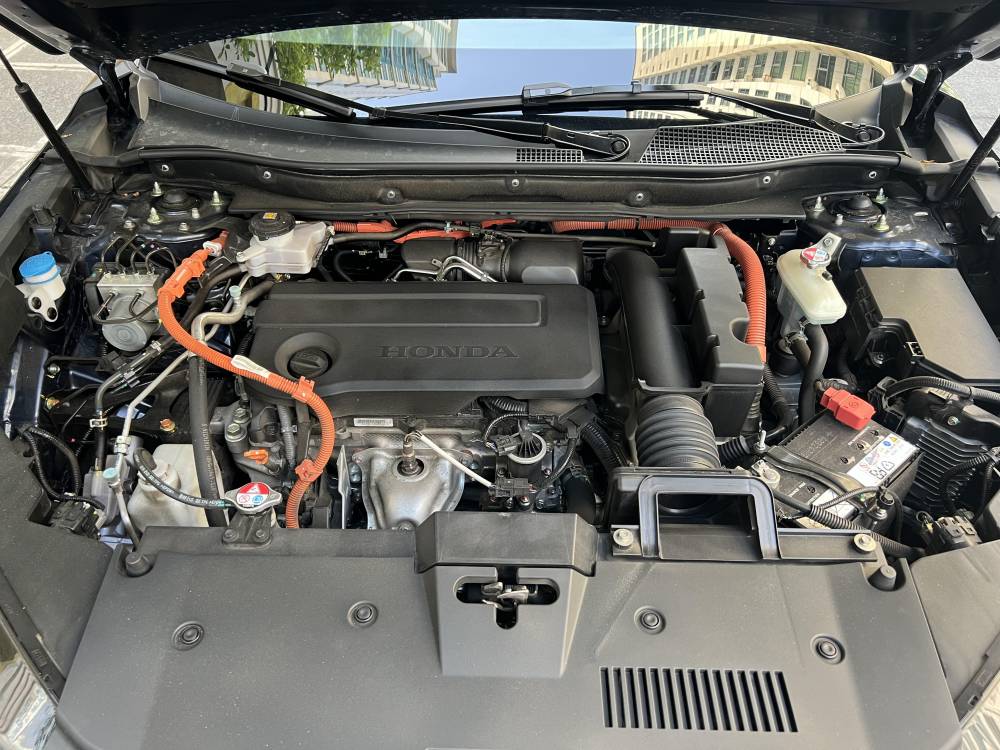

When the world’s biggest producer of cars shows serious intent to recycle and dismantle its end-of-life vehicles, that should make other big companies pay attention.

I wrote about the dismantling program of Toyota Motor Corp last November when I talked to Pras Ganesh, executive vice president of Toyota Daihatsu Engineering and Manufacturing, who said that one of Toyota’s major efforts in Asia has been its dismantling program for cars that have reached their end-of-life stage. He said that Toyota has been on the lookout for parties who could be trained on how to dismantle old cars in the most environmentally friendly way possible–“the best way of scrapping using the least emissions” were his exact words.

In the Philippines, he revealed that a couple of sites have been given a closer look. The target for Asia is to establish at least 10 dismantlers to practice Toyota’s “proper end-of-life vehicle scheme.”

LFP battery 90% recyclable

BYD, the global leader in new-energy vehicle (NEV) production, revealed during its recent launch of the Sealion Super DM-i compact SUV, that it uses lithium iron phosphate (LFP) battery for its EVs.

LFP is a specific type of lithium-ion battery which has a long service life, requires little to no maintenance, is extremely safe, lightweight, efficient, and recyclable.

According to the Acrobat consortium of researchers, more than 90% of the critical raw materials in LFP could be recycled by 2030.

According to the BYD Ireland website, the patented BYD Blade battery adopts the LFP technology and is said to be 100 percent recyclable. And when it has provided enough service as an EV battery, it can serve its “second life” in energy storage for households. In the Philippines, there have been no announcements yet in as far as BYD’s recycling programs are concerned.

VinFast’s recycling plans

Meanwhile, another EV maker–Vietnam-based VinFast—has recently announced it has been collaborating with partners to make the recycling and reuse process more efficient, cost-effective, and environmentally friendly.

VinFast EVs also use LFP batteries, which have been known to rely less on scarce resources like cobalt and nickel compared to lithium-ion batteries. VinFast says this characteristic not only enhances the performance and safety of its vehicles, but also simplifies the recycling process and minimizes their potential environmental impact.

In 2022, VinFast partnered with Li-Cycle, a leading lithium-ion battery recycler whose innovative technology allows for the recovery of up to 95% of battery materials. This closed-loop process ensures that recovered materials can be used to manufacture new batteries, creating a sustainable cycle for these valuable resources.

VinFast is also exploring repurposing solutions for spent batteries. In 2023, it signed a memorandum of understanding with Japan’s Marubeni Corp to collaborate on developing battery energy storage systems using recycled EV batteries. These systems can store excess energy from renewable sources, providing a reliable and sustainable power source.